OFFERING UPGRADES OR NEW TURN-KEY FACILITIES FOR FOUNDRIES

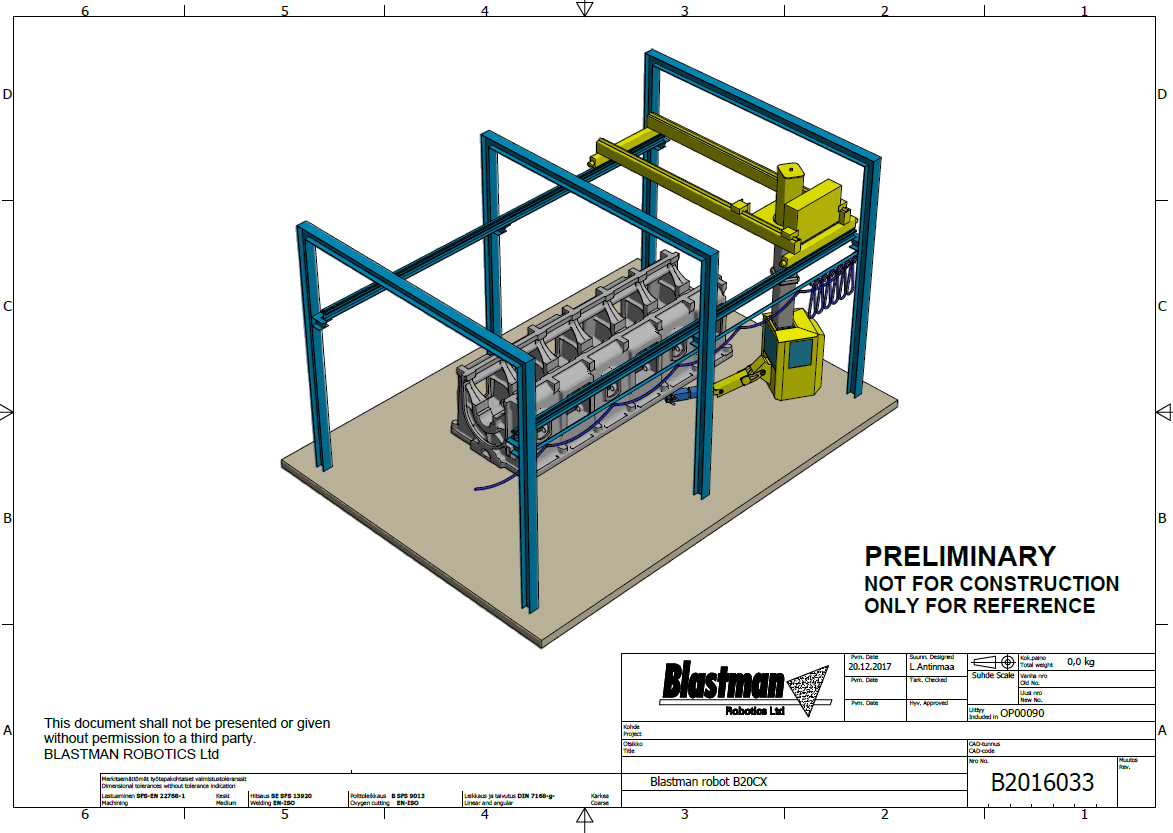

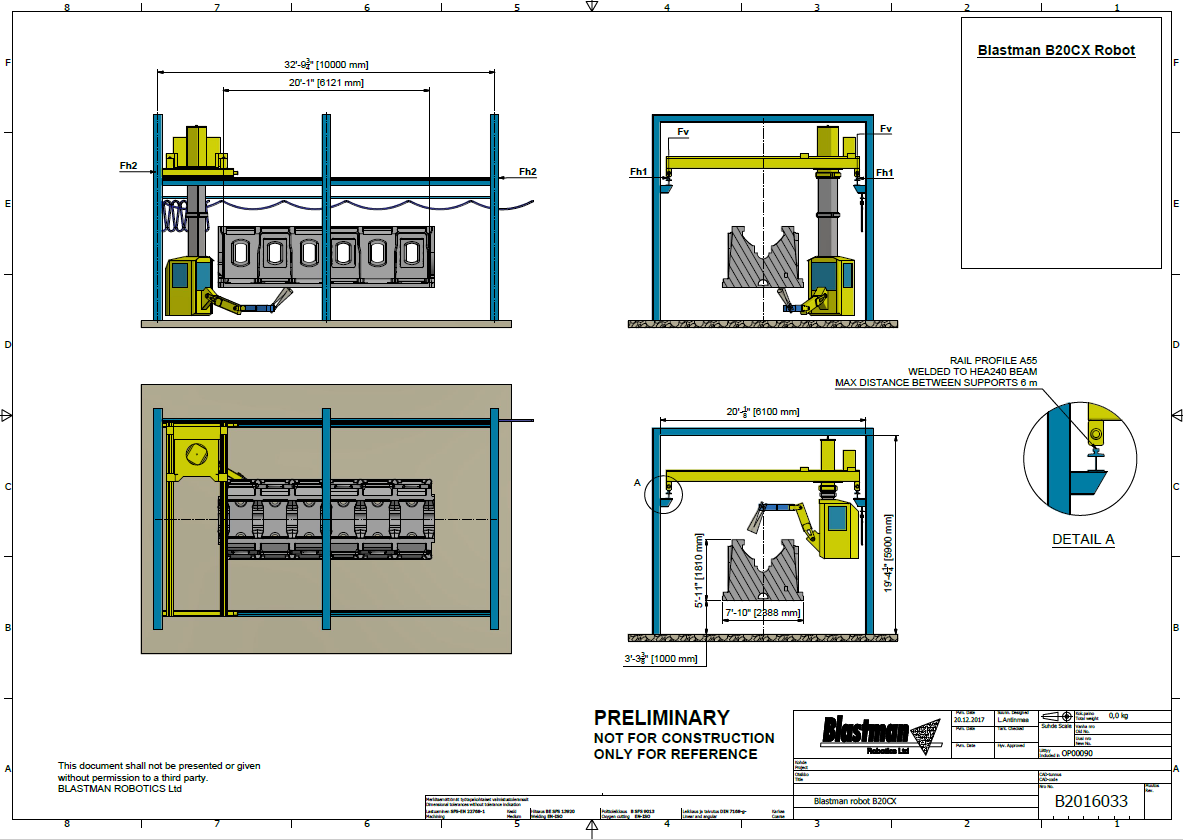

BlastOne are experts in the design, engineering, construction and support for blasting and painting facilities in foundry environments. We have some clients that only need paint and blast equipment for completing their project, or some just need design engineering services to conceptualize their plan, others seek upgrades to existing equipment, and still others need full turn-key supply and construction of the facilities. We are noticing a trend in the equipment industry, whereby managers are finding themselves under quality, profit margin, and/or production pressures – leading to interest in ways of automating their processes. In the right circumstances, BlastOne has robotic and semi-autonomous solutions which can revolutionize production times.