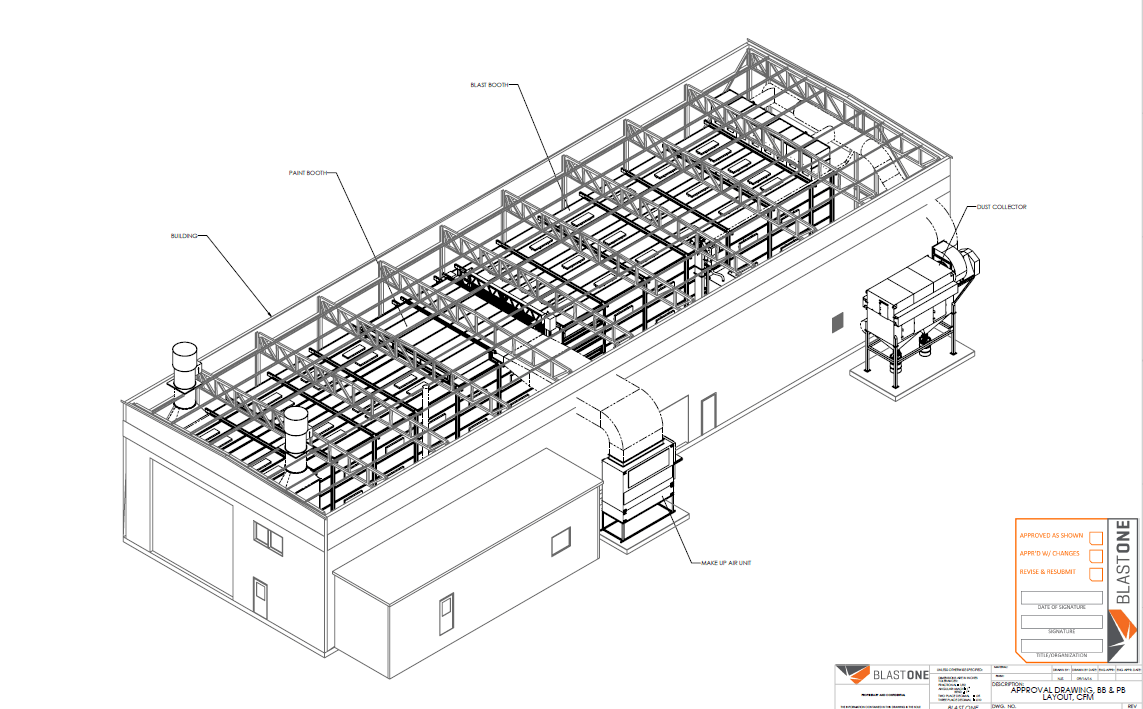

BOOTHS LARGE ENOUGH TO ACCOMMODATE HEAVY EQUIPMENT

BlastOne staff are experts in engineering, design, construction and support for blasting and painting facilities in the heavy equipment industry. Some clients need only design engineering services to conceptualize their plan, others need just blast and paint equipment for completing the work, others seek upgrades to existing equipment, and still others need full turn-key supply and construction of the facilities. We have noticed a pattern in this industry, where there is a lot of pressure on managers regarding profit margin, quality and efficiency. This has caused pressure on managers in the equipment industry, as they are lacking profit margin, production and quality. This has encouraged them to look in to automation. BlastOne’s robotic solutions are a great option to increase efficiency.