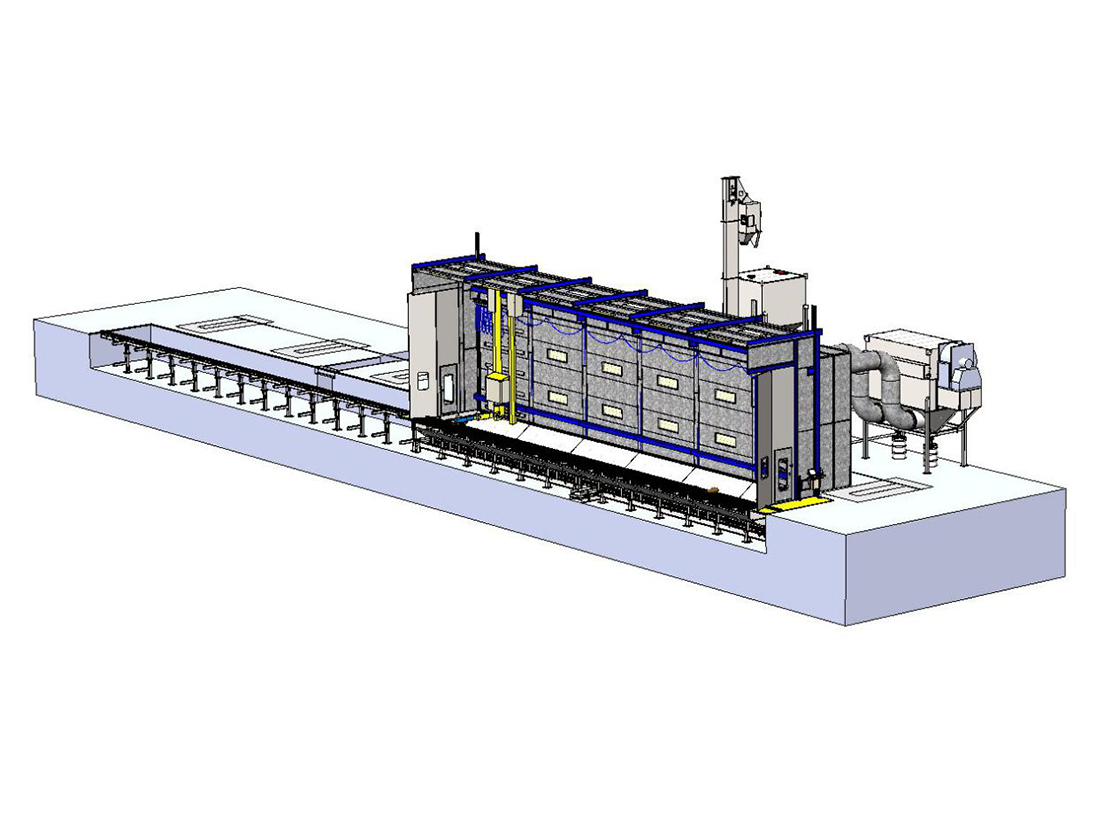

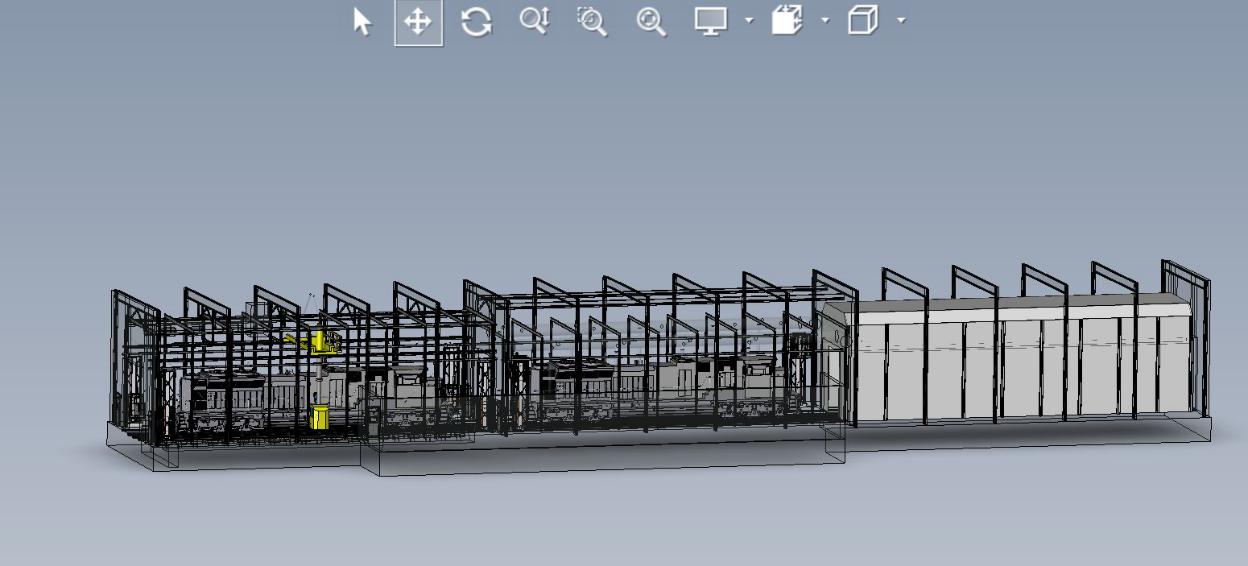

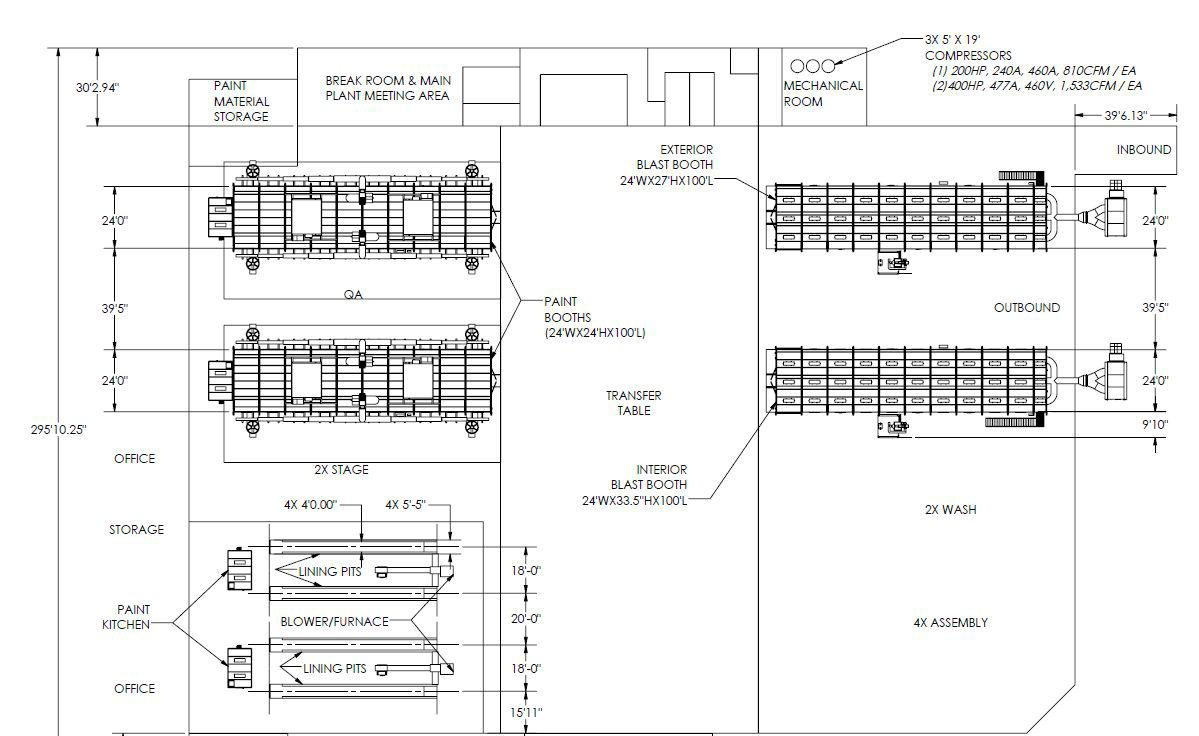

RAILCAR PAINT BOOTHS AND BLAST ROOMS

BlastOne’s 40 plus years’ of experience in the design, engineering, construction and support of facilities for blasting and painting sets us apart from our competitors. We have experience in blasting and painting all types of rail rolling stock, including all types of locomotives, railcars, and rail passenger vehicles. Some customers need just design engineering services, others need just blast and paint equipment for completing the work. We also have customers that need us to handle the construction of their facilities and turn-key supply. Here at BlastOne, we are noticing a trend in the equipment industry, whereby managers are finding themselves under quality, profit margin, and/or production pressures – leading to interest in ways of automating their processes. For the right projects, BlastOne has autonomous solutions that can revolutionize production times.