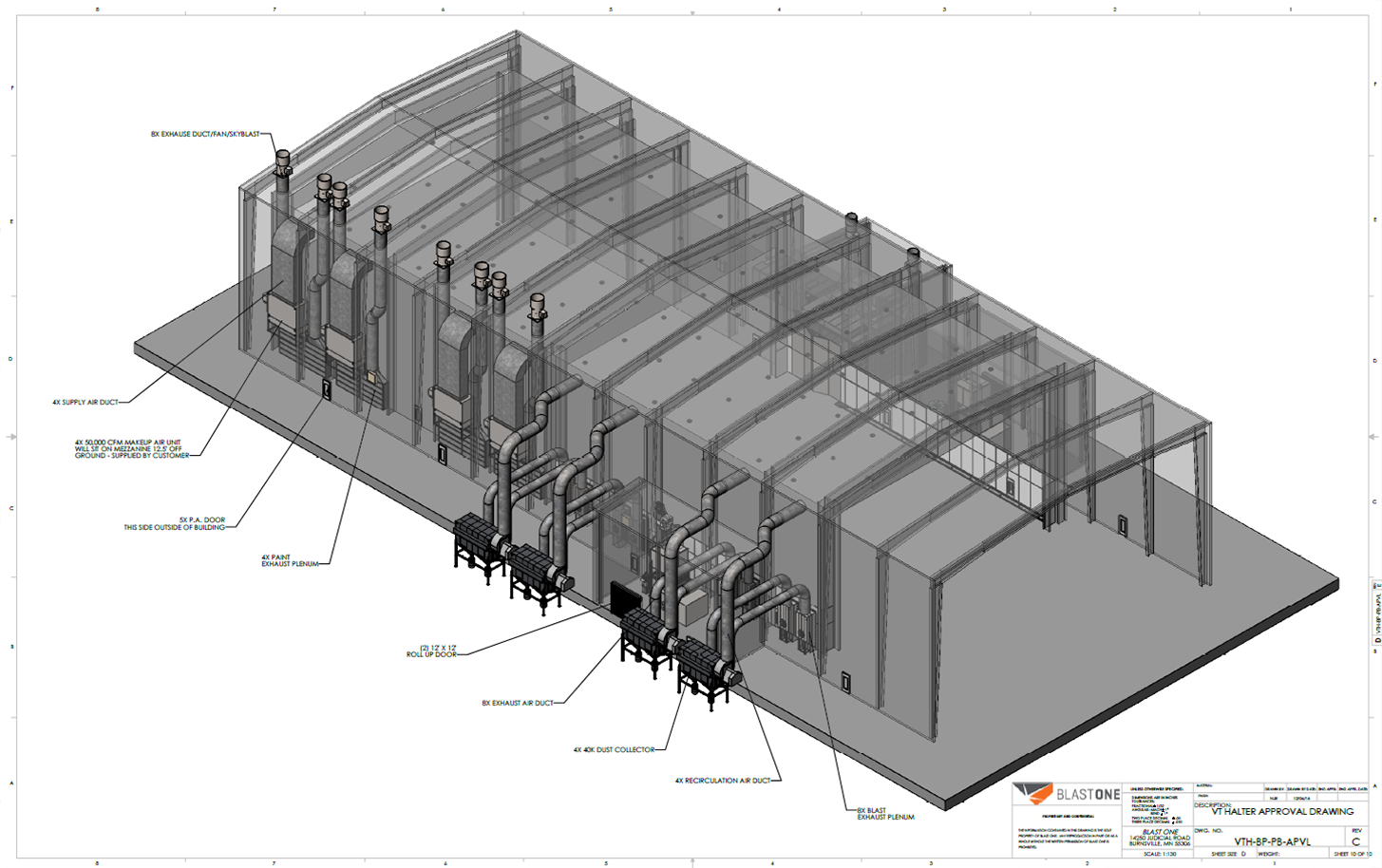

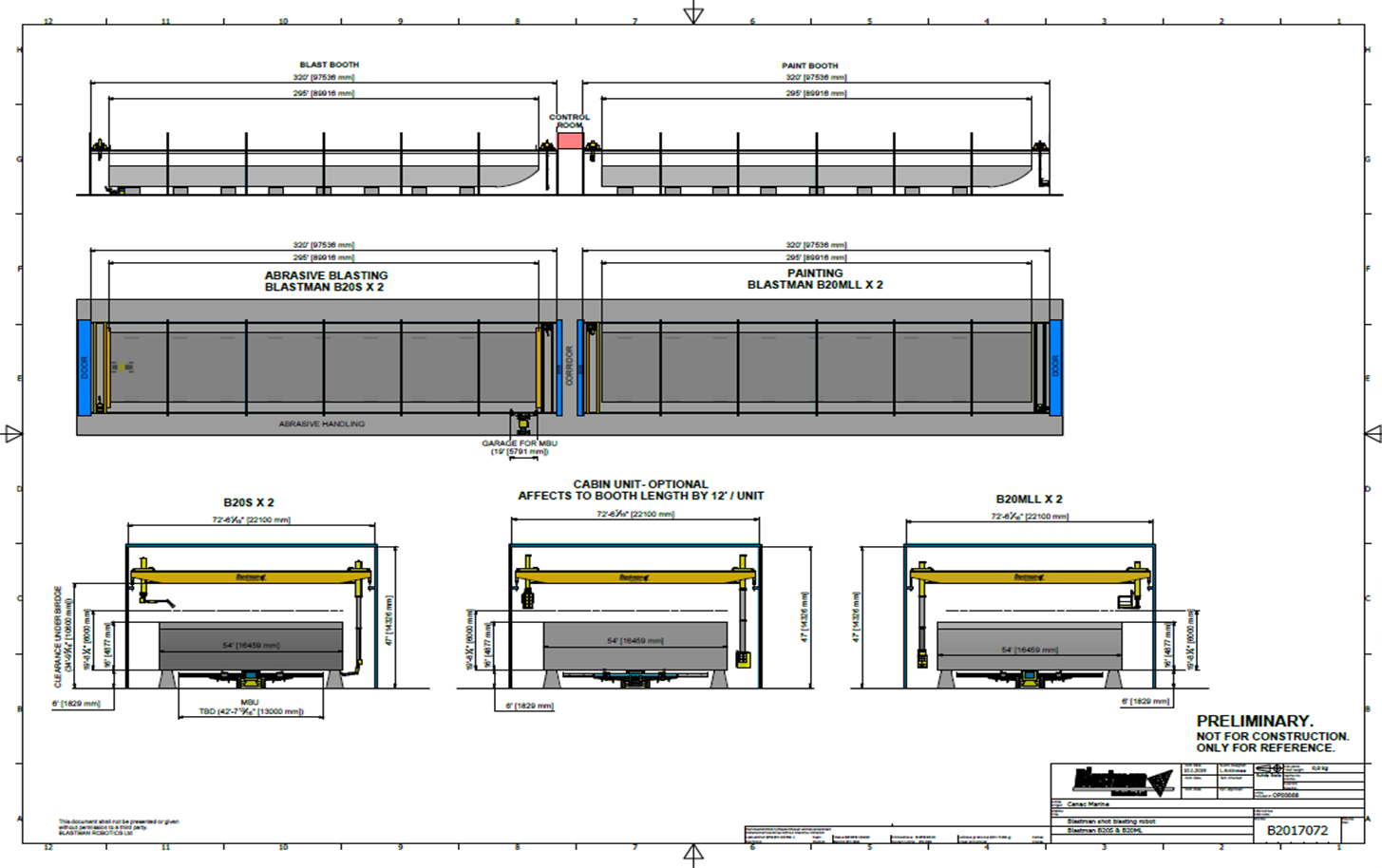

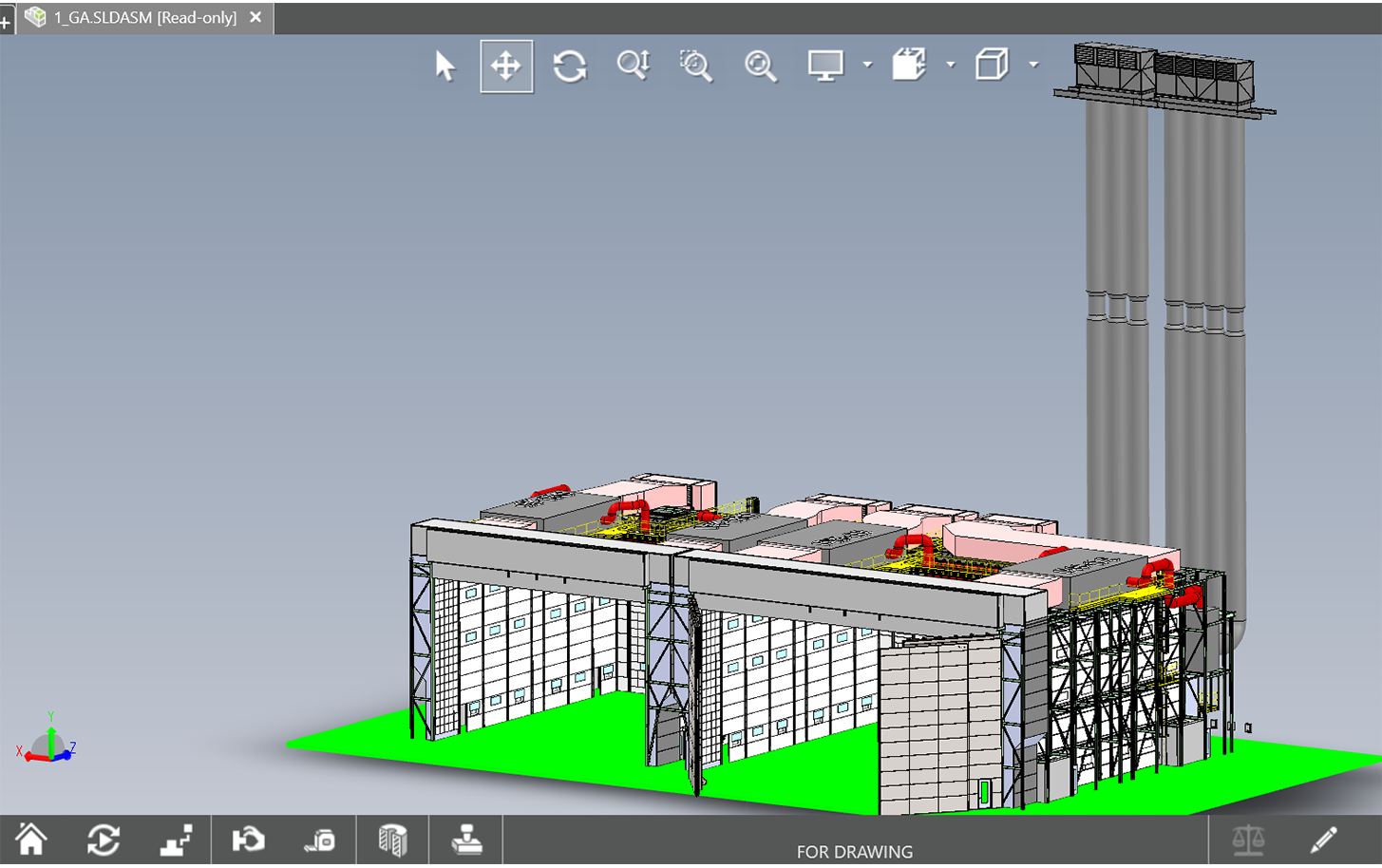

BOAT AND SHIP PAINT BOOTHS AND BLAST ROOMS

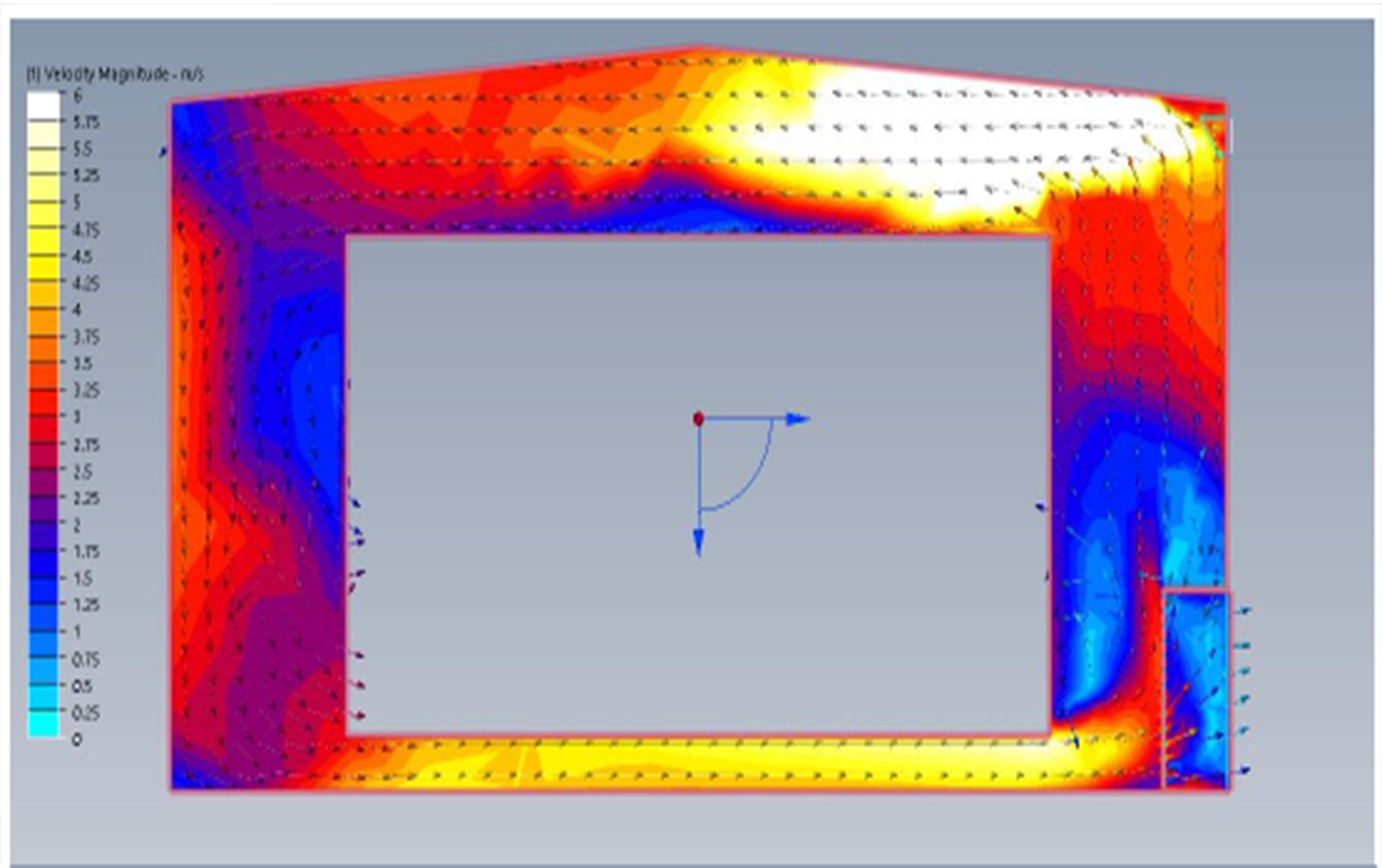

BlastOne has been making blasting and painting safer, more efficient and cleaner for over 40 years. We have been painting and blasting all types of marine vessels, including boats and ships. While a group of our clients need full construction and fully equipped supply, whereas some only need blast and paint equipment in order to finish their projects. Over the last few years, we have realized that project managers in the equipment industry are feeling pressured because they are under profit margin, production or quality. This has guided people to look deeper into automation. In the right circumstances BlastOne has robotic and semi- autonomous solutions which can revolutionize production times.